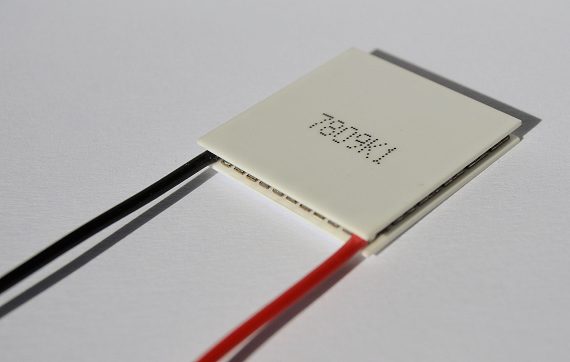

TM 71-1.0-4.0 Thermoelectric Cooling Module

Specifications with Thot = 27 °С

Part Number |

Imax |

Umax |

Qcmax |

∆Tmax |

Dimensions (mm) |

TM 71-1.0-4.0 |

3.9 |

8.8 |

18.7 |

70 |

20 x 20 x 3.6 |

Multi-purpose module TM 71-1.0-4.0 is a rather powerful 20 x 20mm cooler intended for use with 5 to 8.6 volt (DC) power sources. Its compact size, excellent cooling capacity and relatively low heat ejection, make the module particularly popular for spot cooling.

Can be used with a very wide variety of economical extruded heat-sinks without the hot-side temperature becoming unreasonably high. It’s also frequently used in strings. For example, two connected in series can be operated from a 12V source (or 15V). Four in series are operated with a 24V source, etc. A combination of parallel strings of modules in series allows coverage of a large surface area.

TM 71-1.0-4.0 may be used for cooling, heating and thermal stabilization and is employed in a wide range of applications including electro-optic/photonic, fiber optic, aerospace/military, telecommunications. A version for thermal cycling is available.

Available with metalized and tinned surfaces.

Comprehensive Specifications (Hot-Side Temperature 27 °C)

Imax = 3.9 Amps (Imax is the maximum current at ΔTmax)

Vmax = 8.8 Volts (Vmax is maximum voltage at ΔTmax)

Qcmax = 18.7 Watts (Qcmax is maximum cooling capacity at Imax, Vmax and ΔT = 0 °C)

ΔTmax = 70 °C (ΔTmax is maximum temperature difference at Imax, Vmax and Qc = 0W)

Internal resistance = 1.95 Ω ± 10% as measured by AC 4-terminal method at 25 °C

Operating temperature range: -50 °C ~ +200 °C (Solder melting point: +235 °C)

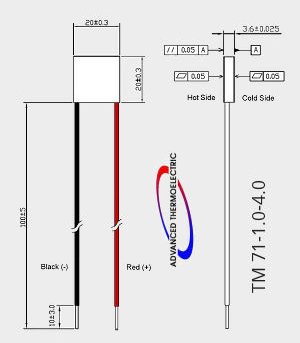

Thickness tolerance: ± 0.025mm (Lapping to ± 0.01mm available.)

Flatness and parallel variance: ± 0.05mm

RoHS Compliant

Standard lead wires: 22 AWG, Tin (Sn) plated at module interface, with a maximum temperature of +105 °C

(Other wiring options available.)

Maximum recommended compression: 1MPa

Ceramics: Alumina (AL2O3)

Metalized (and tinned) surfaces available

The lot number is printed on the center of the cold-side

Options & Designations (Suffix):

(for example: TM 71-1.0-4.0 "EL")

- Epoxy edge sealing = "E"

- RTV edge sealing = "RTV"

- Lapping to ± 0.01mm = "L"

Drawing

Dimensions in mm

Useful Links

- Thermoelectric Module Overview

- Module Specifications

- Thermoelectric Fundamentals

- How A TEC Works

- Installing TE Modules

- TE Module Reliability

- Epoxy Edge Sealing

Please contact us for a quotation. sales@electracool.com or (603) 888-2467.

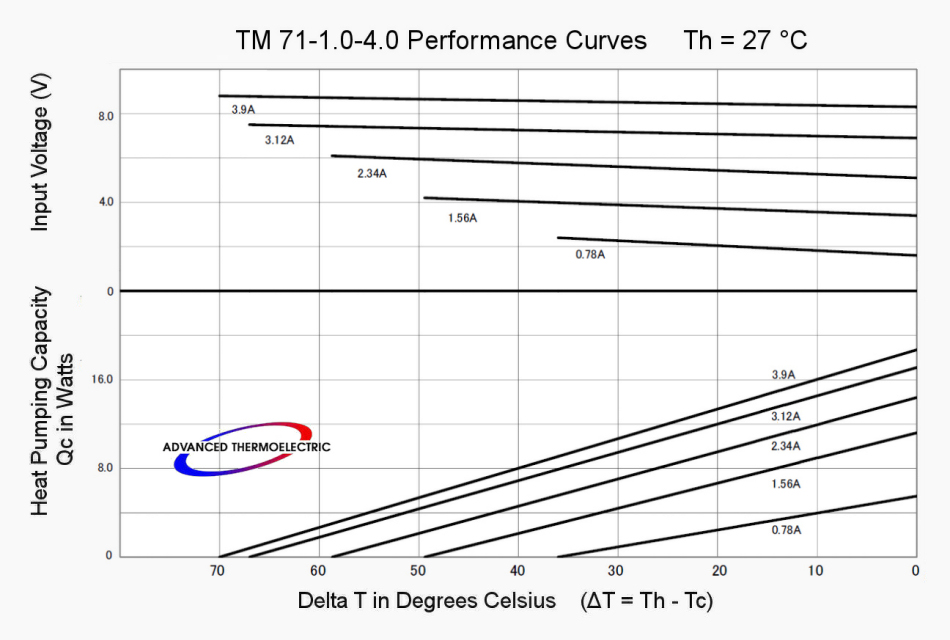

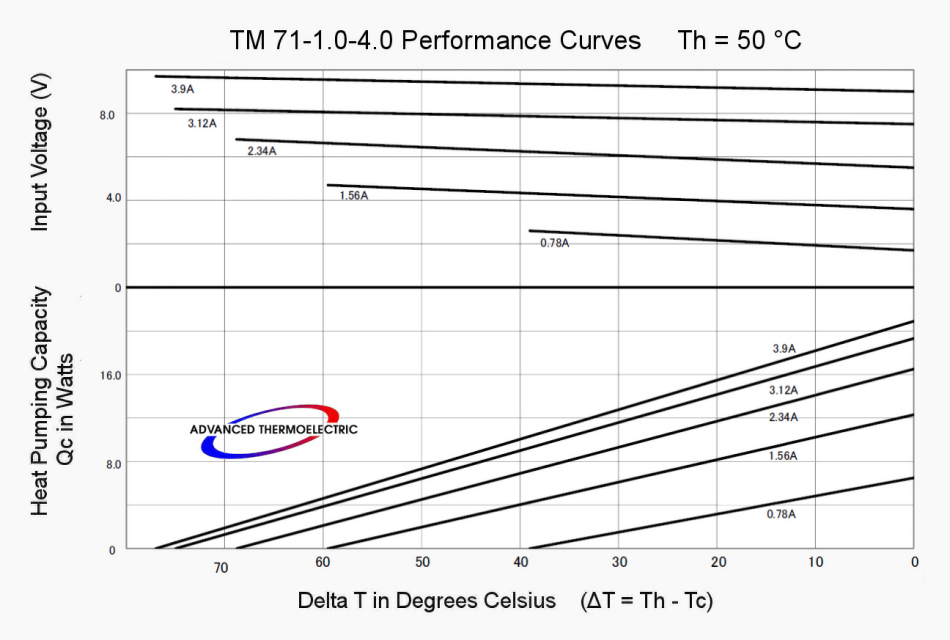

Performance Curves (click image for enlargement)

Thermoelectric module performance curves are graphical representations showing the relationships between power applied and net cooling for a specific TE module.

Performance curves are valuable tools for quickly determining if a TE module is a suitable COOLER for an application; learning what power is required for an appropriate module to reach the desired temperature and heat pumping capacity; and to provide the basic information necessary for proper assembly design.

Curves with Th = 27 °C indicate what to expect operating in ambient temperatures around 20 °C (70 °F) with an operational "hot-side" temperature or Th about 7 °C above ambient.

Curves with Th = 50 °C are for outdoor, box-in-box, and other applications with ambient temperatures in the 40-50 °C range.

sales@electracool.com

Toll free in North America: 1 866.665.5434

International: 603.888.2467