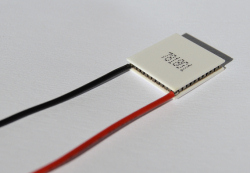

TM 71-1.0-6.0 Thermoelectric Cooling Module

Specifications with Thot = 27 °С

Part Number |

Imax |

Umax |

Qcmax |

∆Tmax |

Dimensions (mm) |

TM 71-1.0-6.0 |

6.0 |

8.8 |

29.7 |

70 |

20 x 20 x 3.1 |

Multi-purpose module TM 71-1.0-6.0 is a powerful 20 x 20mm cooler intended for use with 5 (to 8.6) volt (DC) power sources. Compact size, excellent cooling capacity and relatively low heat ejection, make this module popular for spot cooling but is also frequently used in strings to control the temperature of a larger surface area utilizing 12V and 24V power sources.

For example, two TM 71-1.0-6.0, connected in series, can be operated from a 12V source (or 15V) while four can be operated from a 24V source, etc. Multiple strings of this type allows coverage of a large surface area.

Can be used with a wide variety of economical extruded heat-sinks without the hot-side temperature becoming unreasonably high. It’s also frequently used in strings.

TM 71-1.0-6.0 may be used for cooling, heating and thermal stabilization and is employed in a wide range of applications including electro-optic/photonic, fiber optic, aerospace/military, telecommunications. A version for thermal cycling is available.

Available with metalized and tinned surfaces.

Comprehensive Specifications (Hot-Side Temperature 27 °C)

Imax = 6.0 Amps (Imax is the maximum current at ΔTmax)

Vmax = 8.8 Volts (Vmax is maximum voltage at ΔTmax)

Qcmax = 29.7 Watts (Qcmax is maximum cooling capacity at Imax, Vmax and ΔT = 0 °C)

ΔTmax = 70 °C (ΔTmax is maximum temperature difference at Imax, Vmax and Qc = 0W)

Internal resistance = 1.05 Ω ± 10% as measured by AC 4-terminal method at 25 °C

Operating temperature range: -50 °C ~ +200 °C (Solder melting point: +235 °C)

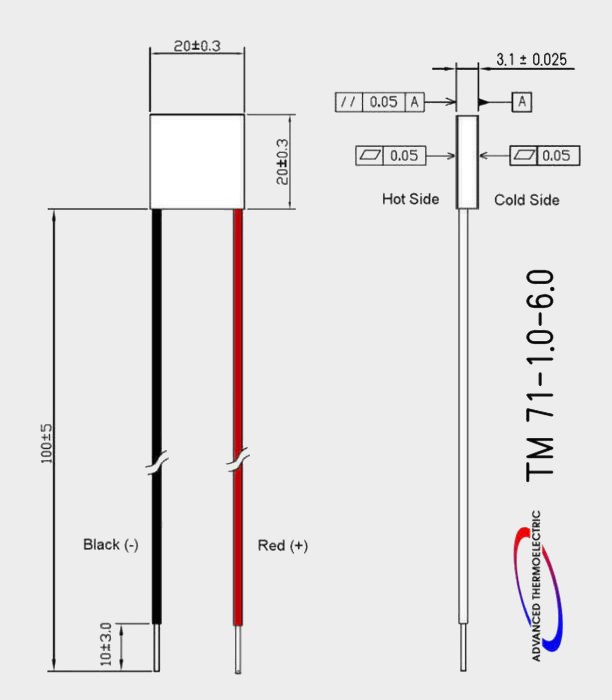

Thickness tolerance: ± 0.025mm (Lapping to ± 0.01mm available.)

Flatness and parallel variance: ± 0.05mm

Standard lead wires: 22 AWG, Tin (Sn) plated at module interface, with a maximum temperature of +105 °C

(Other wiring options available.)

Maximum recommended compression: 1MPa

Ceramics: Alumina (AL2O3)

Metalized (and tinned) surfaces available

The lot number is printed on the center of the cold-side

RoHS Compliant

Options & Designations (Suffix):

(for example: TM 71-1.0-4.0 "EL")

- Epoxy edge sealing = "E"

- RTV edge sealing = "RTV"

- Lapping to ± 0.01mm = "L"

Drawing

Dimensions in mm

Useful Links

- Thermoelectric Module Overview

- Module Specifications

- Thermoelectric Fundamentals

- How A TEC Works

- Installing TE Modules

- TE Module Reliability

- Epoxy Edge Sealing

Please contact us for a quotation. sales@electracool.com or (603) 888-2467.

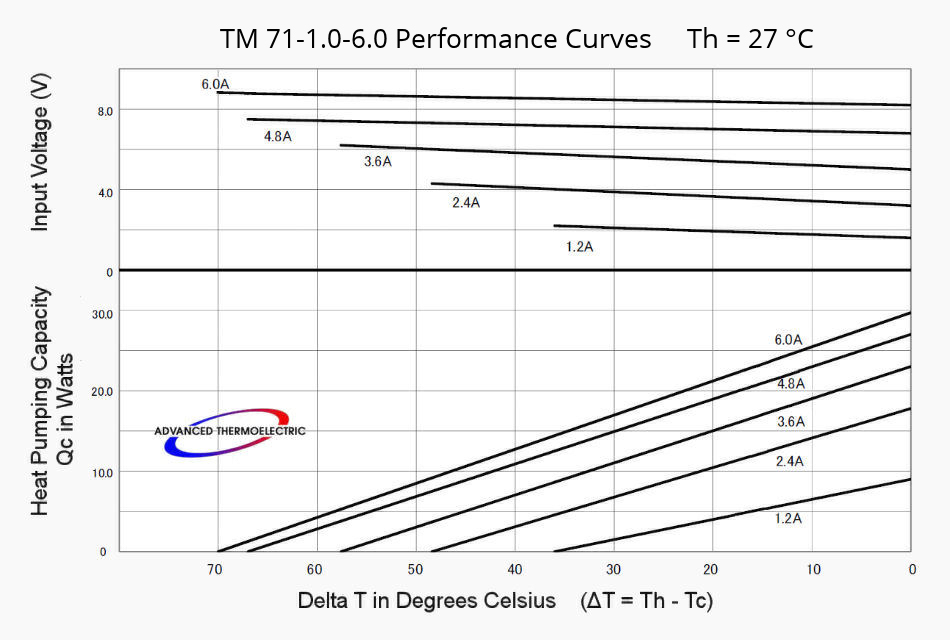

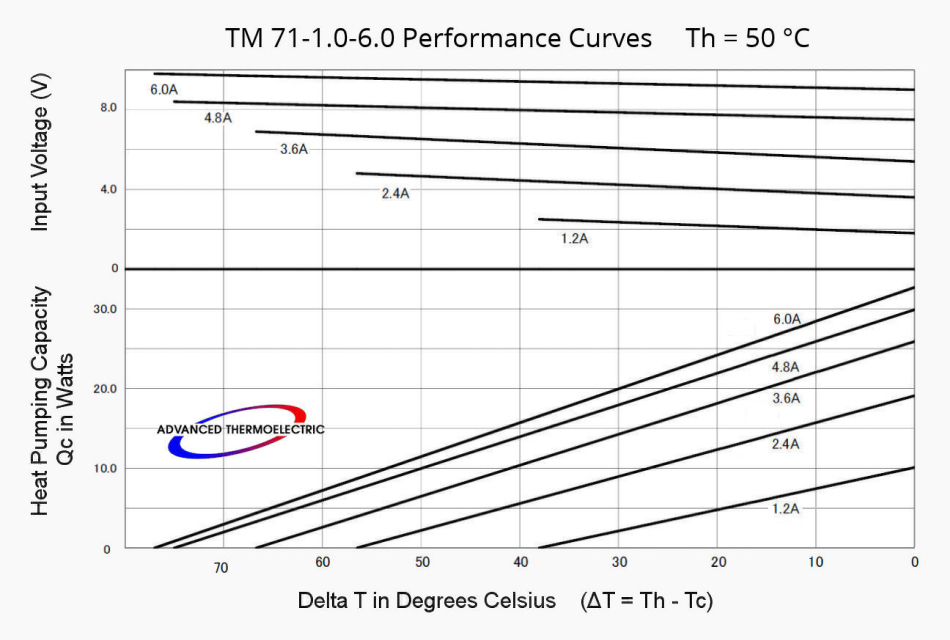

Performance Curves (click image for enlargement)

Thermoelectric module performance curves are graphical representations showing the relationships between power applied and net cooling for a specific TE module.

Performance curves are valuable tools for quickly determining if a TE module is a suitable COOLER for an application; learning what power is required for an appropriate module to reach the desired temperature and heat pumping capacity; and to provide the basic information necessary for proper assembly design.

Curves with Th = 27 °C indicate what to expect operating in ambient temperatures around 20 °C (70 °F) with an operational "hot-side" temperature or Th about 7 °C above ambient.

Curves with Th = 50 °C are for outdoor, box-in-box, and other applications with ambient temperatures in the 40-50 °C range.

sales@electracool.com

Toll free in North America: 1 866.665.5434

International: 603.888.2467